How to make money on the jobsite.

MATERIAL HANDLING

Any time we can reduce the number of pieces that have to be moved on a jobsite, it is a win for contractors. And when facing staffing challenges, it has become even more important to improve processes so projects can be completed without disruptions. Here are a few ways that Encore Wire can help to get the job done smarter:

- Save time with custom labels

- Handle less reels

- By combining shorter length runs reducing number of reels

- By ordering your pulls paralleled instead of individual reels

- By having your single or paralleled feeder runs layered onto one reel

- Reduce man-hours by using installed iTool pulling heads

- Utilize Cyclone Barrel Packs® or the PullPro® for circuit pulls

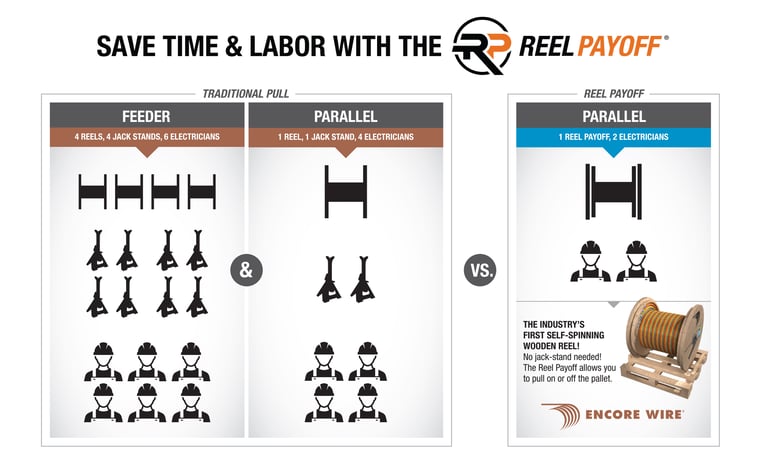

- Reduce manpower needs with The Reel Payoff® (see infographic below)

- Utilize an instant pay-out system like the MC Barrel Pack

ON-TIME DELIVERIES

For many contractors, timing is critical. Material is needed when it is requested so jobs can move forward as planned, and client expectations are met. That's why distributors and contractors choose to partner with Encore Wire for time-sensitive projects. The manufacturer's 720,000 square foot Service Center allows for less handling, fewer shipments, reduced overall costs, and an unrivaled level of service.

.jpg?width=720&height=540&name=bobtail%20(1).jpg)

PRODUCT AVAILABILITY

In addition to being the fastest to deliver material, Encore Wire lives up to its reputation for providing quality, reliability and some of the highest fill rates in the industry. Among the manufacturer's competitive differentiators is its vertically integrated, single-site campus located in McKinney, TX. Additionally, global supply disruptions are avoided as the campus's input needs are met within a 1,000 mile radius.

OTHER WAYS YOU CAN MAKE MONEY

With quick accessibility and productivity-enhancing solutions, fewer labor hours are required and less waste is accumulated. Plus Encore Wire's Scrap Purchase Program is available so that you can turn your scrap into cash. The in-house recycling program reclaims insulated and bare copper through a chopping process, allowing you to cut out the middleman and put more money in your pocket. Additional benefits from partnering with the industry-leading wire and cable manufacturer include the following:

- American-made products

- Innovative solutions

- Blazing fast output, while not sacrificing quality for speed

- Top-notch customer experience

- Honesty & dependability

- Collaborative approach with customers

- Continually striving for 100% fill rate

- Labor saving solutions